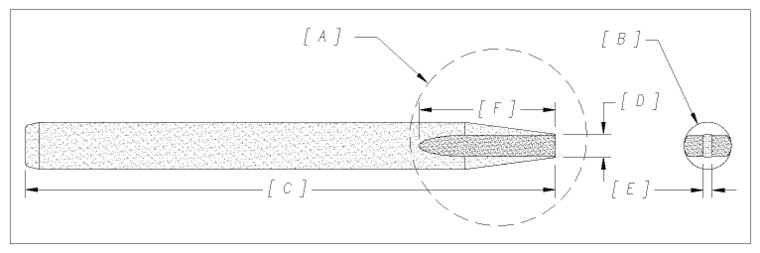

Explanation of Tip Measurements

- Tip Configuration - The basic shape of the soldering tip's working area, with the most common being variations of chisel, diamond, conical and screwdriver (pictured above).

- Tip Diameter - Measured around the shank of the tip, the diameter of the soldering tip must match the diameter of the soldering iron's tip compartment.

- Tip Length - Tips must be long enough to fully seat inside the soldering iron's tip compartment.

- Width of Working Area - Often a key measurement, along with tip configuration, that determines suitability for a tip to a specific soldering application, especially where tight areas are concerned.

- Thickness of Working Area - Usually a thicker working area equates to more available heat.

- Tapered Distance of Working Area - Another measurement that effects accessibility.

Information on Tolerances

Tip/Electrode measurements shown on this website are approximations. During the manufacture of our tips and electrodes, there are multiple machining and plating processes. Each of these processes carries a different tolerance. This makes it very difficult to provide meaningful tolerance measurements for the final product. Each tip/electrode is intended to be used in its 'related' American Beauty product. If you intend to use our tips and/or electrodes in other tools, where the knowledge of exact measurements and tolerances are required, please email or phone (800.550.2510) our technical support team.